|

Worlds leading producer of new equipment and OEM parts for |

Made in the USA |

| Products > Kimwood Sanders > Control Master | ||

|

Kimwood Machinery Inc. offers the STATE-OF-THE-ART in wide-belt sanders. Kimwood's impressive history of successful installations has made Kimwood sanders the standard from which many others are judged. Dating back to 1960, the basic design philosophy for all Kimwood equipment continues today.... a heavy duty machine capable of combining high production while producing the finest sanded panels in the industry. Our ongoing policy has been one of product and service commitment to the forest products industry. Click the following link to check for "New or Reconditioned Equipment" currently in stock. | |

|

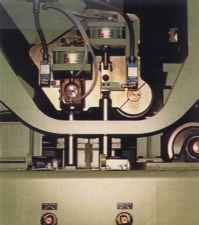

Industry Standard:The Control Master is designed especially for precise sanding and finishing of particleboard and MDF panels. The Control Master Sander is capable of high production, fine finishing and holding close tolerances. The Control Master is available in 4' to 9'-6" widths and can be equipped with a variety of head styles, depending upon the specific application such as the type of panels, stock removals, feed speed and finishes required. |

Typical Sanding Heads:

| |

Orifice Sanding Principle:One of the keys to accurate and precise sanding is Kimwood's patented "orifice" sanding feature which is used on the Kimwood Control Master Sander. Because of the tremendous pressures created across the face of panels while being sanded, it is important that the design of the sander include a controlled orifice (opening) through which the panel must pass. Not only is the creation of the opening important, but also the maintaining of the opening under actual sanding load is equally important. The actual orifice is created and maintained utilizing air cylinders, adjustable columns and slide blocks which all comprise the actual sanding head assembly. |

|

|

Tracking Adjustments:The tracking cylinder causes the tracking roll to pivot on its axis in short intervals resulting in an easy oscillation of the sanding belt. By adjusting the stroke limiting knobs, the operator can change the rate of speed that the belt drifts, making sure the tracking roll is steering sufficiently. The tracking cam adjustment is designed so the operator can rotate the cam while the machine is running allowing tracking abrasive belts easier. |

Retrofits:Kimwood has been involved in the manufacture of sanders for the wood products industry since 1963. Through the years, the sanders have continually been updated to accomodate specific industry applications which characterize the everchanging industry. As the applications have changed so have certain areas of the sanders. In some cases, Kimwood has introduced new models to meet new applications or modified existing models simply to remain competitive in the industry. Irregardless, Kimwood sanders remain the leading sander in the industry today. Click "Sander Retrofits" for available sander upgrades. Roll Inventory Program:The Roll Inventory Program was introduced in September of 1999 when Kimwood began stocking rolls that were in the highest demand. Kimwood has now implemented a revised program that will increase the number and type of rolls held in inventory via component stocking rather than assembled rolls. Component stocking will allow more individual roll parts to be placed in inventory which are used on multiple roll assemblies. This will be advantageous and will increase our ability to meet the high demand rolls needed to help customers during downtime situations. Click "Roll Inventory Program" for more information. Parts, Manuals, & Assembly Drawings:Kimwood maintains historical files for all of it products lines. As a result of this, almost all of the equipment originally supplied can be manufactured from historical files. Kimwood also can reproduce most machine assembly drawings and original manuals for those pieces of equipment. Click "Parts, Manuals, & Assembly Drawings" for more information. Sander Trade-in / Reconditioning Program:Let us look over your present Kimwood Sander and provide a trade-in allowance against the purchase of a new Kimwood Sander; or as an alternative, let us provide a price to recondition your existing sander. Click "Reconditioning Program" for more information. | |

Kimwood Machinery Inc. |

77684 Hwy 99 South |